What is a Perforated Cable Tray? Uses and Benefits of Perforated Cable Tray

09-August-2021 || By: Admin

Any construction of a building has to include 3 huge designing accomplishments. It incorporates electrical, mechanical and civil works. When executing wiring inside the structure premises, there are a few perspectives which are to be thought of. One of the significant fundamental just as vital segments of any structure related electrical wiring is link the executives. Directing flawlessness of electrical wires is very urgent for legitimate working. Consequently, certain items are to be utilized to empower a safe climate for the two individuals and wires. One significant material which guarantees more prominent structure wellbeing is Perforated Type Cable Trays.

Classic Perforated cable trays are used for instrumentation, Control as well as Power Cables. Perforated Cable Trays provide excellent ventilation, it enhances life of cables and it can be fixed to any structure. The NEC says a cable tray system is a unit or assembly of units or sections and associated fittings forming a structural system used to securely fasten or support cables and raceways. That said, raceways generally mount on a wall in a room where power and communications cables are terminated.

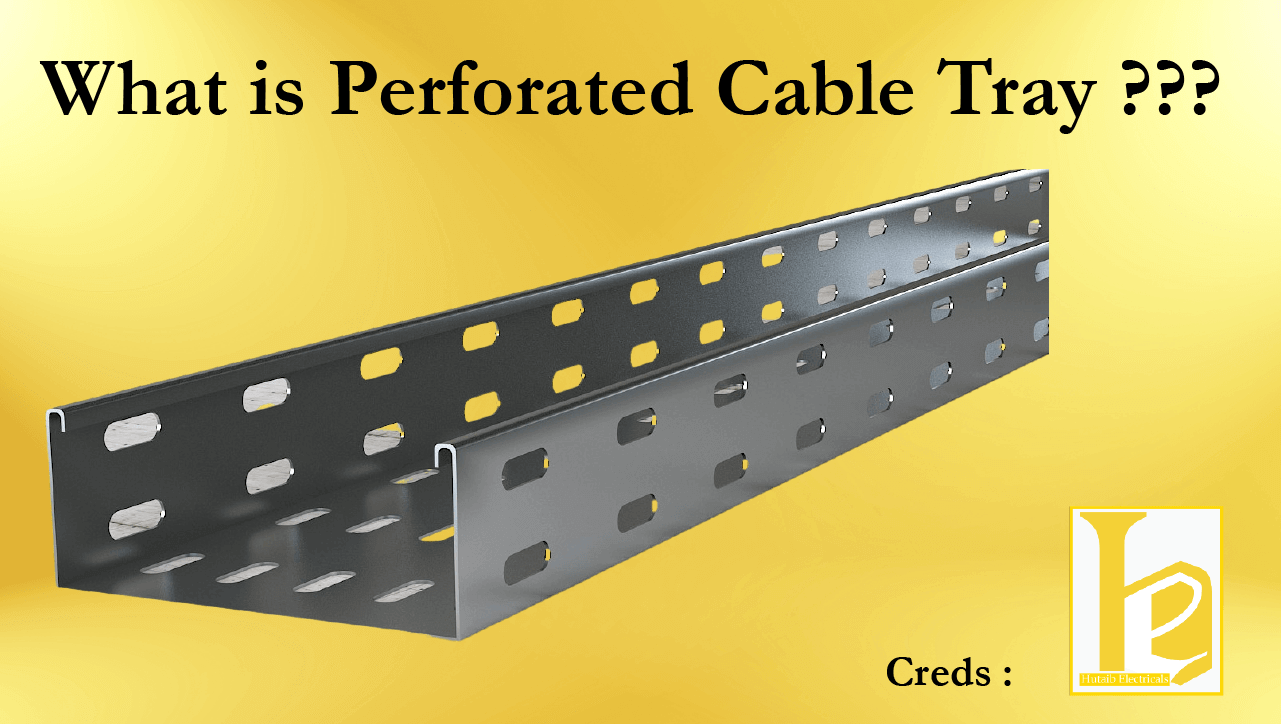

Cable Tray - Perforated Type

are ideal to install large volumes of Heavy duty power cables. Perforation makes full free air rating of cable ,Higher current flow can be achieved at the same cross section , Overheating and consecutive damaging of cable is avoided ,coupler holes inside guarantees easy connecting of cable trays to each other.A cable tray system upholds and secures both force and signal cables and works with updating, growing, reconfiguring, or moving networks.

The majority of the cable tray systems are open, permitting proficient warmth scattering and simple access for substitution and fixes. Although commonly suspended from roofs or appended to dividers, some cable tray systems are reasonable for underfloor use.

Perforated cable tray

consists of a ventilated base with side rails. It offers more help to links than the stepping stool type, Solid-bottom Cable Tray. Solid-bottom Cable Tray for fiber-optic link establishments where hanging of cables might influence framework execution, strong base (non-ventilated) cables trays are liked.In any case, the fundamental justification for choosing a strong base plate is a worry for electromagnetic/radio-recurrence impedance security.

Uses of Perforated Cable Trays:

Perforated cable trays are parts of support techniques for force and information cables and wires. A perforated cable tray custom supports and jams both force and sign links and assists with overhauling, expanding, reconfiguring, or moving channels. Perforated cable tray techniques are open, permitting compelling warmth circulation and simple way for substitution and fixes. Although regularly suspended from rooftops or appended to dividers, punctured link plate strategies are good for underfloor use.

Features of Perforated Cable Trays:

- Solid construction for conveying a wide range of cables.

- Perforated cable trays have openings on base to give sufficient ventilation and position to link lines.

- Hostile to consumption, fire, dampness because of the pre-aroused, hot-plunged powder covered, epoxy covered completion.

- Phenomenal warmth scattering.

- Protected and smooth edge shields cable lines without any preparation.

- Sufficiently able to withstand short circuits.

- Accessible in all sizes.

- Adaptable, simple and fast establishment.

- Extraordinary development configuration permits cable trays to go anywhere.

- Accessible in different assistants to fix and introduce.

- Simple to keep up with.

- Long life expectancy.

Benefits of Perforated Cable Trays:

Less expensive: One of the huge advantages of utilizing a perforated

cable

tray is that it costs significantly not exactly different frameworks of guarding wiring on the stock

floor.

Backing: Perforated Cable Tray is promptly apparent for help checks, developing of cables is

simple

since wires can enter or leave the Perforated Cable Tray anytime of the activity.

Security: Regular housework is significant for security, as Perforated Cable Tray is frequently

settled

in difficult to move places.

Specifications of Perforated Cable Trays:

Material: Hardened steel 304/316, carbon steel Q195/235, pre-stirred

steel,

aluminum, FRP/GRP.

Finish: Pre-stirred, hot-plunged electrifies, electro aroused, powder covered, epoxy covered.

Length: 2000mm - 6000mm.

Width: 50mm - 1500mm.

Thickness: 1.0mm - 4.0mm.

Stature: 15mm - 250mm going from light, medium to weighty.

Accessories: Base join plates, side graft plates, development graft plates, even flexible join

plates,

vertical customizable graft plates, right/left reducer graft plates, flat elbow, even tee, even cross,

level reducer, vertical elbow up, vertical elbow down, connector, and so forth

Packing: Stuffed in stretch film then in a wooden box or as indicated by your prerequisite.

Hutaib Electricals is a well-known Manufacturer, Supplier, and Exporter of an outstanding variety of Perforated Cable trays in Pune, India. If you've got any questions or need some assistance together with your applications, contact us today for more information. Hutaib electricals cable trays are known for their various features like corrosion resistance, durability and reliable performance. And Customers can buy these from them at the market leading prices. We will definitely help you to get the best

Perforated Cable Trays in India

We are Cable Tray Manufacturer & Supplier in Pune Mumbai & India.

Do Visit Our Product Page